Special Projects Gallery

300 Ton Bridge

This building started out as a car bridge over the Green River in Tukwila WA. It was moved to private property in the early 1980’s and set on a concrete foundation with concrete walls and was used as a sandblasting building for heavy equipment.

It needed to be moved to allow for new road construction, so we were contracted to move it approximately .5 of a mile and place it on a new slab.

The challenge was to move it up the hill and turn it on a compound angle with no room for error.

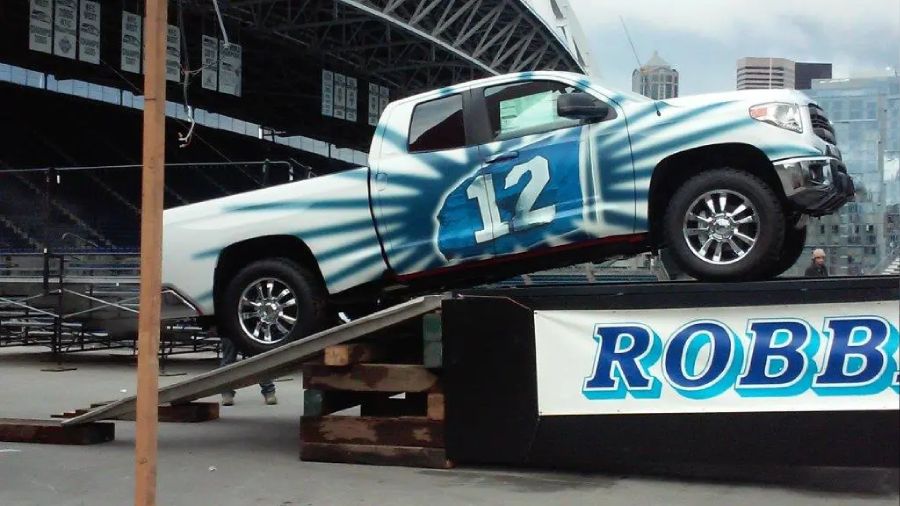

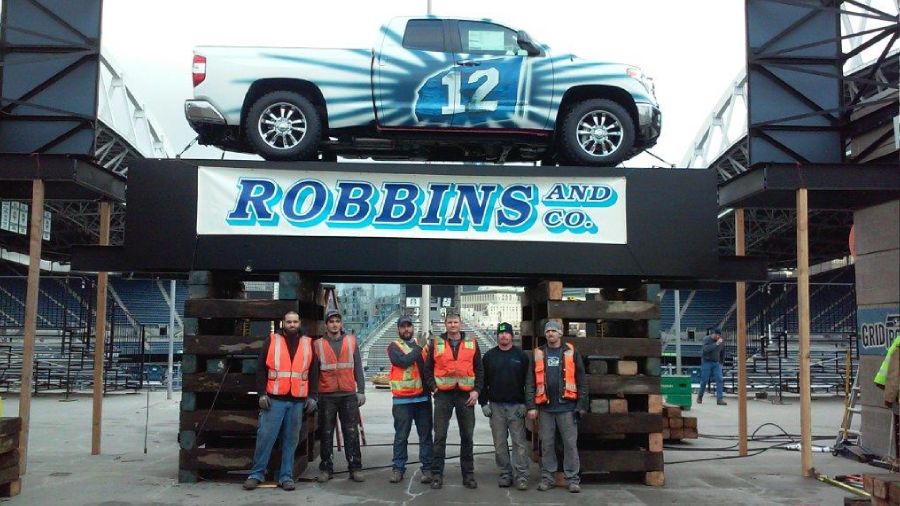

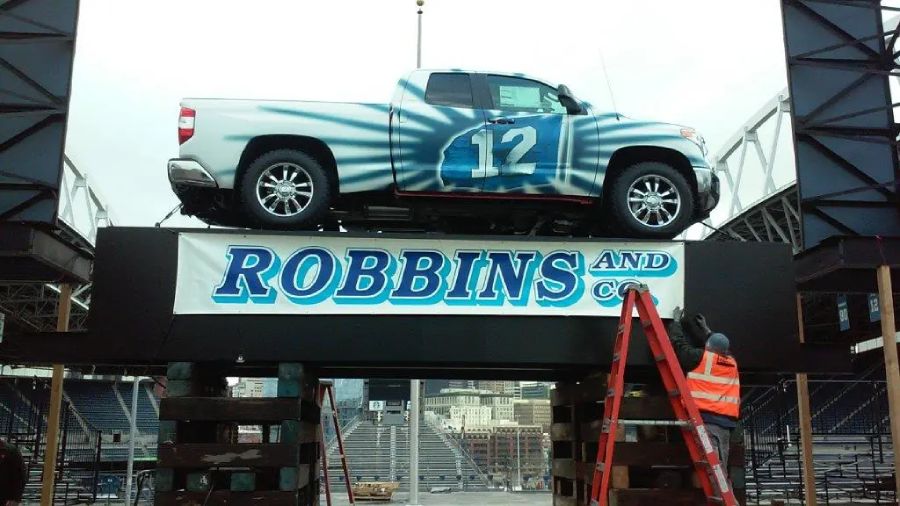

Centurylink Field Gallery

Totem Pole Gallery

This move involved an actual Indian totem pole reaching 20 – 25 ft tall, and was being relocated to a new location onsite. One of the more difficult aspects of this project was the difficulty to determine the center of gravity in order to flip it from being vertical to go horizontal for the move. A custom clamp had to be built to fit around the pole in order to maneuver and move it. Also, a ceremonial act had to be performed by the Indians before it could be moved. It is tribal tradition to have a ceremony to put the totem to sleep before it can be moved. And then again to wake up the sprites of the totem after it has been placed in its new location.

Sculpted Wood Carving Gallery

Robbins and Company was contracted with the arduous task of moving a 2,300 lb sculpted wood carving from Orcas Island to downtown Seattle for C.C. Filson Co. There were many hours of very careful planning, preparation, logistics and coordination for this installation to be successful. The logistics for the operation became constrained, when we received the final OK for the move and installation with less than 7 days to go.

When we were chosen to do the project on a Saturday, it had to be installed that Thursday. We met with Filson again on a Monday and sent drawings for brackets for engineering. By Tuesday, received engineer approval and ordered the steel for fabricating the brackets. On Wednesday, we drove to Orcas Island to load the 18.5 foot sculpture. Then on Thursday, we loaded all the rigging equipment, assembled the crew and mobilized to the site for installation of the giant structure.

It took four months for artist and wood sculptor, Aleph Geddis, to design and carve this one-of-a-kind piece of art for the Filson flagship retail store in Seattle. Utilizing hand-made tools and an unique style formed through an appreciation of North West Coast Native Art and travels around the world, Aleph, with the help of his carving team, has created a 18.5 foot testament to the wild spirit of the Northwest.

John Doe

Spruce Goose Gallery

If you remember from history, the Spruce Goose was designed and built by Howard Hughes intended as a transatlantic transport for use during World War II. (It was not completed in time to be of use.) The Hughes H-4 Hercules is a prototype heavy transport aircraft designed and built by the Hughes Aircraft Company, and this move was interesting for a few different reasons.

The timing had to be expedited due to the fact part of the move went across a highway, so that highway had to be closed. The gigantic plane was dismantled into 4 different sections, with the fuselage weighing over 400 tons alone! The Spruce Goose had been delivered to the Evergreen Airport and Robbins and Co needed to carefully maneuver it over a mile to its new home at the Evergreen Aviation & Space Museum. There was an air show happening at the same time and became a big news event.

Tree Replacement Gallery

This project came to us from a previous customer. The back story is that the property owner above had topped two trees to better the view. As it turns out, the two trees belonged to our customer and he didn’t give permission to top the trees. The challenge was to place two 8,000 lb 25’ ft tall trees up on to the hill side about 300’ ft.

Several ideas were tossed around form a large enough crane to reach the site, but cost and access to the site would not accommodate such a large crane. We looked into using a helicopter but the cost and the safety factor were too high. We were not able to use any equipment to carry the trees due to how steep the terrain was. We choose to go with structural scaffolding and roll the trees into the hillside. But that only got the trees part of the way because we had to jack them up about 8’ ft and continue rolling them into the hillside. We also had to move one of the trees sideways approximately 30’ ft, and stand them up without the use of any power equipment. The project from start to finish took about six days.

Camp Waskowitz Gallery

Tank was feeding the drinking water system as well as the fire hydrants water supply. Prior to fixing the tank, two separate systems needed to be built, so that drinking water and fire suppressions for the hydrant water could be pumped through a pump house. And while beginning the project, we used three 10,000 gallon tanks to hold water during construction.

The camp wanted to keep exterior of tank, which was made of red cedar wood, so the best solution was to pour a 24 inch concrete pad, and shotcrete the walls 12 inches thick. Approximately half the roof had to be ripped off and replaced. Also, While installing the drinking water system also installed conduit and vaults for future high voltage and data systems.

REPLACING WORRY WITH PEACE OF MIND

Serving the Pacific Northwest since 1952…72 YEARS. Contact us for free estimate.